TBM-1 Thermal Break Material

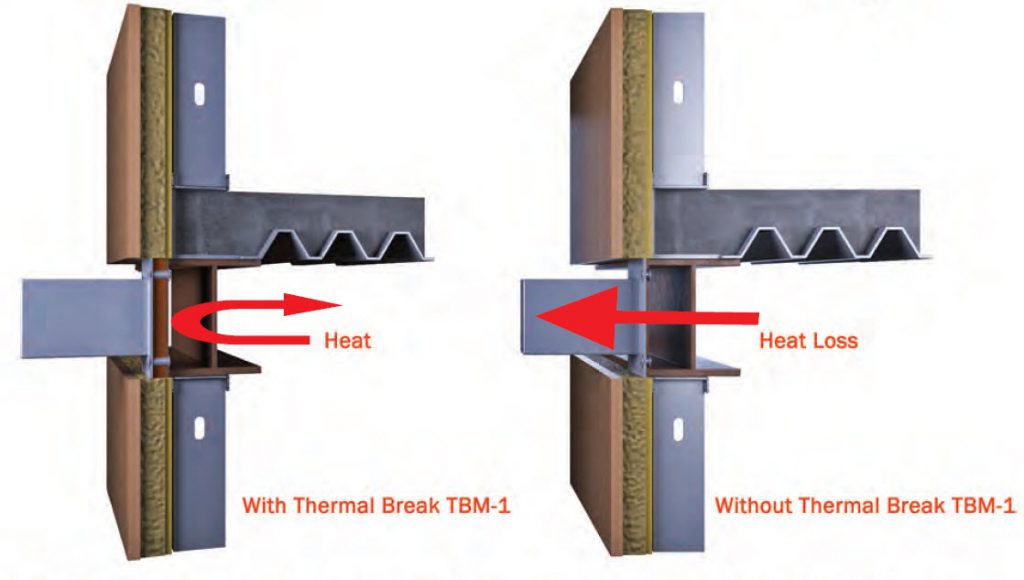

Reduce heat loss due to thermal bridging. Structural thermal break material for steel to steel or steel to concrete connections.

The purpose of thermal break materials and systems (thermal breaks) is to reduce the impact of thermal bridging by preventing conductive heat flow through the building thermal envelope. Thermal breaks also help to keep surface temperatures within the thermal envelope above the dew point. This eliminates potential condensation risk.

To be effective, a thermal break has to have a much, much lower thermal conductivity than the material it is “breaking”. Bell Rubber is the exclusive fabricator of TBM-1 material for Thermal Bridging Solutions. (Thermal Break Material™ (TBM-1) conducts heat 1200 times less than aluminum, 300 times less than steel and 80 times less than stainless steel.

For all materials, conductance is a function of thickness and heat flow is a function of thickness, area and temperature. Therefore, the thickness of the thermal break material and the connection design will determine how much heat loss is prevented. Thermal break washers and bushings are used with Thermal Break Material™ to reduce the heat flow through the bolts in the connection.

Thermal break material is a reinforced, thermoset composite which exhibits low to no creep under load and transfers loading conditions up to 30,000 psi. It also has very good fire properties.